Technical Reference

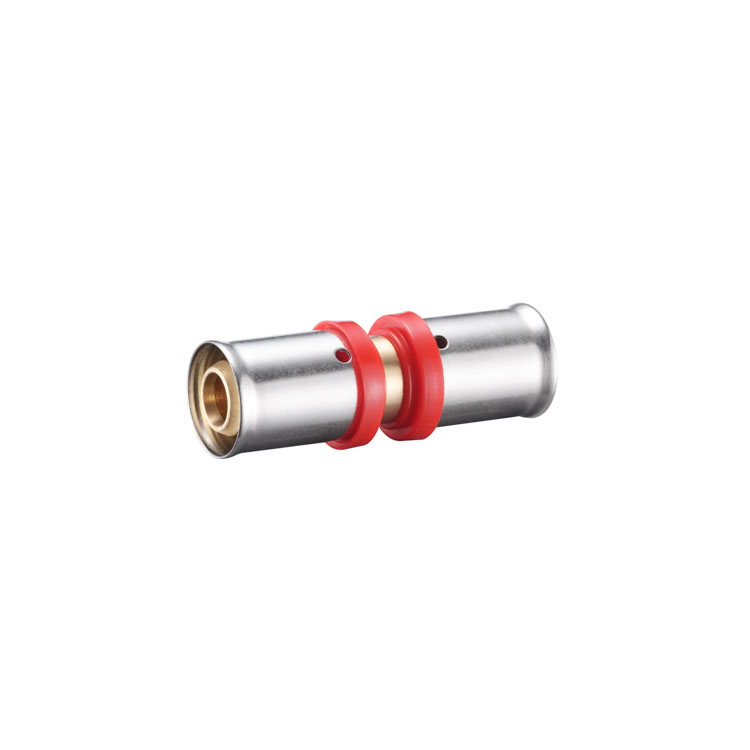

| Main Components | Brass body, 304 stainless steel sleeve, PE seat, EPDM O-ring |

| Working pressure | ≤1.0 MPa |

| Medium | Oil, water, gas |

| Working temperature | -10°C to +95°C |

Structure Description

The main material of the steel sleeve press fittings is brass, and the O-ring material is EPDM rubber.

Structurally, each fitting is equipped with two O-rings that function as dual seals after installation.

When thermal expansion or cold contraction occurs between the pipe and the fitting nipple, the O-rings automatically rebound and reseal to prevent leakage.

Additionally, the stainless steel sleeve plug surface features three grooves, which form a wave structure after being compressed by the tool.

This design ensures highly reliable sealing performance.

Advantages

1. Stable Installation

Traditional compression fittings rely on threaded connections, which are prone to loosening and require regular maintenance. In contrast, the new press fittings utilize a press tool for assembly. Once installed, no further maintenance is required, ensuring long-term structural integrity.

2. Cost-Effectiveness

By replacing brass hex nuts with 304 stainless steel sleeves, material costs are reduced by approximately 30% while maintaining durability. This design optimizes both initial investment and lifecycle expenses.

3. Additional Features

Corrosion Resistance: Certified to withstand aggressive media (pH 4-10), with a service life exceeding 50 years (per ASTM B117 salt spray test).

Health Compliance: Meets NSF/ANSI 61 standards for drinking water safety.

High-Rise Adaptability: Engineered for high-pressure stability (≤1.6 MPa), suitable for vertical pipe systems in skyscrapers.

Installation Efficiency: Compatible with ergonomic press tools (e.g., hydraulic or battery-operated), enabling rapid connections in confined spaces.

English (United Kingdom)

English (United Kingdom)  简体中文

简体中文